Pollution and Waste Management

Supporting the SDGs Goals

Stakeholders Directly Impacted

Goals and Performance Highlights

Commitment, Challenge and Opportunity

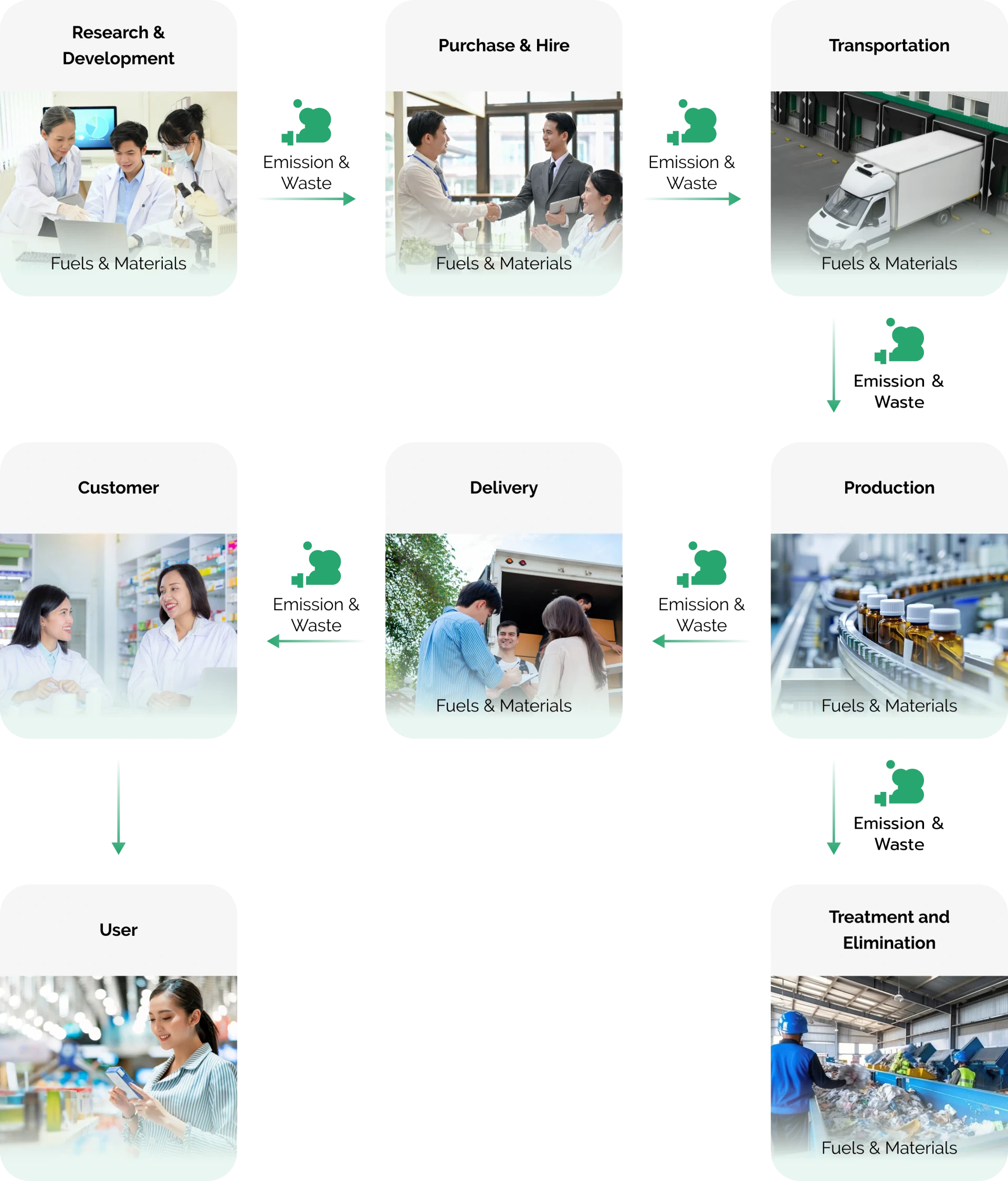

BLC has a policy to reduce waste in the production process, lower costs, reduce expenses, and minimize pollution for maximum efficiency. The identification of causes leading to environmental impacts is part of the Life Cycle Assessment (LCA) process, which is an important method for understanding the impacts of various activities from the beginning to the end of the product’s or process’s life. This helps in making better environmental decisions. The LCA process considers resource use, pollutant emissions, and environmental destruction that occur at each stage of the product or service life cycle.

Management and Operational Approach

In managing pollution and waste, BLC follows the ISO 14001 environmental management standards. The company classifies waste and identifies discarded items for employees to separate waste correctly for disposal according to legal requirements through authorized agencies.

BLC selects contractors that use the most environmentally friendly waste disposal methods, although some waste is still disposed of via landfilling. The company is actively seeking contractors who can use more environmentally friendly disposal methods or improve waste quality for more sustainable disposal methods.

Furthermore, the company communicates and campaigns for employees to be aware of the importance of waste reduction, such as reducing plastic straw usage by switching to reusable or biodegradable straws, using cloth bags or baskets instead of plastic bags, and carrying reusable water bottles or cups instead of disposable plastic bottles. This is part of the ongoing promotion of waste reduction and sustainable environmental preservation.

In 2024, BLC collected waste weight data and production weight data for analysis. This data will serve as the baseline year to establish waste management measures for 2025. The company will also communicate with employees regarding waste reduction strategies through internal communication channels such as Line@, bulletin boards, and email

Note : Valuable waste began to be recorded in 2024. (Valuable waste refers to waste that is not harmful to human health or living beings and can be composted.)

The pollution management of BLC is divided into two main parts: wastewater management and emissions from exhaust stacks. For wastewater treatment, the company has a total of four zones designated for wastewater treatment systems, which handle discharges from production processes in different areas. The wastewater is treated through biological treatment processes, both aerobic and anaerobic. Regular monitoring, analysis, and evaluation of wastewater quality are conducted monthly by internal units and tested three times a year by external agencies registered with the Department of Industrial Works. The company uses treated wastewater for watering plants within the company premises without discharging it externally. The total amount of treated wastewater in 2024 can be summarized.

To control emissions from exhaust stacks, BLC measures the amount of toxic substances released annually in accordance with the Ministry of Industry’s regulations on air pollutants from factories B.E. 2006. This is to monitor and control air quality and reduce environmental impacts from company activities. These measurements help assess the amount of dust emitted and verify compliance with legal standards. In 2024, the measurement was conducted on October 22, 2024, and results showed compliance with legal requirements