Supply Chain Management and Raw Material and Product Inventory Management

Supporting the SDGs Goals

Stakeholders Directly Impacted

Goals and Performance Highlights

Commitment, Challenge and Opportunity

Sustainable supply chain management is one of the company’s strategies to enhance business competitiveness. The group places importance on evaluating the environmental, social, and governance (ESG) impacts of various activities in the supply chain, including the procurement and purchasing process, production process, quality inspection process, information technology, storage, transportation, and delivery of goods to customers or consumers. All of these processes play a crucial role in the sustainable growth of the business. Therefore, the group selects and assesses the risks of external service providers to pass on value and responsibility through high-quality products and services, ensuring maximum customer satisfaction and reducing business risks that may arise from negative impacts by external service providers.

Management and Operational Approach

The group has established a Code of Conduct for external service providers, covering environmental issues, human rights, fair employment and working conditions, occupational health and safety, as well as business ethics of external service providers.

BLC sets an operational plan to improve the supply chain management efficiency as follows:

The company evaluates external service providers based on the ESG criteria and develops a plan to promote and encourage external service providers’ participation in ESG and sustainable business development.

In 2024, BLC adjusted the proportion of box purchases for product packaging by selecting sources of production closest to the company to reduce environmental impacts from transportation, while considering other important factors such as quality and better pricing, in line with the plan to reduce raw material and packaging costs as follows:

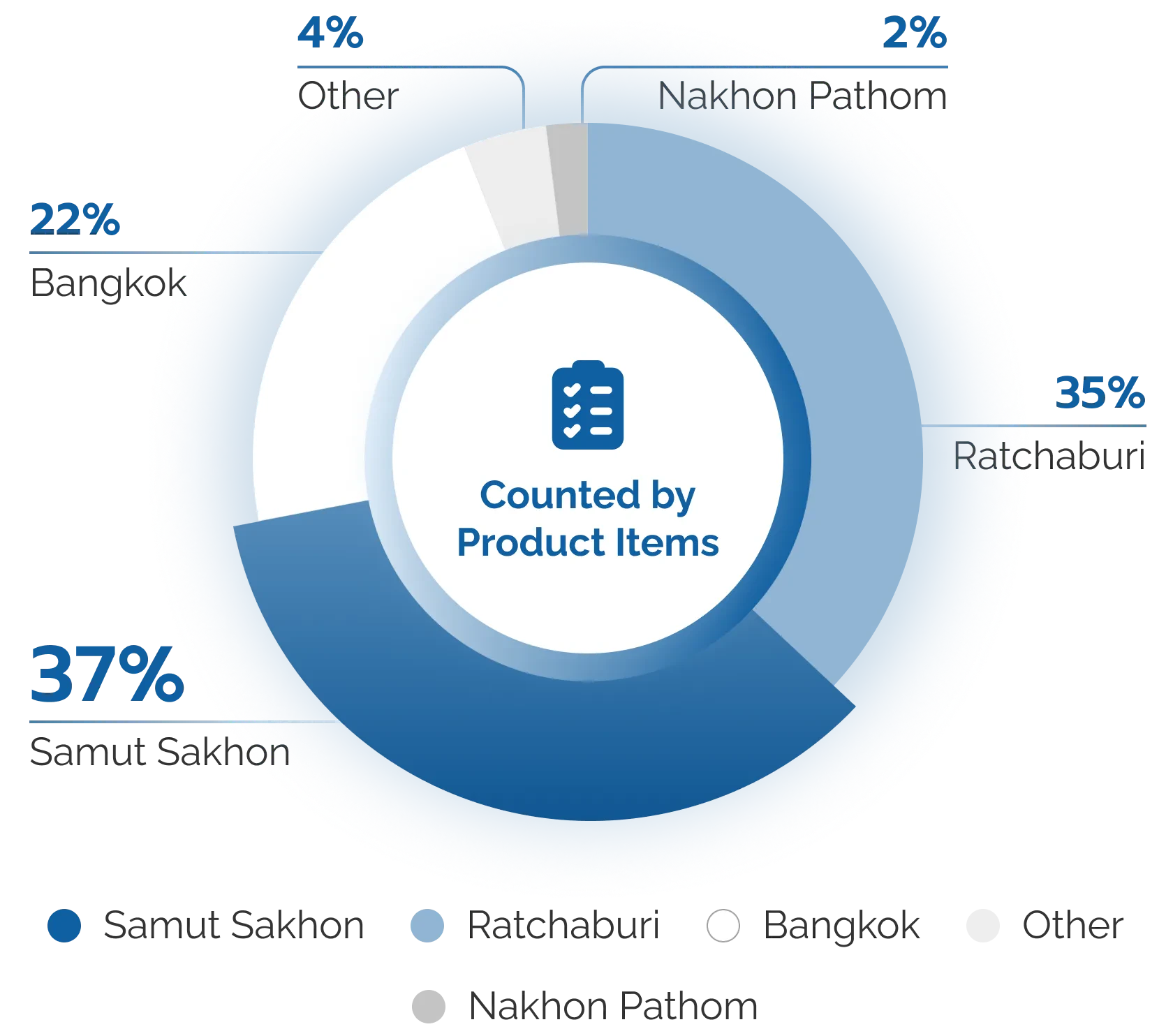

Proportion of the external service provider's location area (counted by product items)

| The external service provider's location area | Product items | (%) |

|---|---|---|

| Ratchaburi | 92 | 35 |

| Nakhon Pathom | 5 | 2 |

| Samut Sakhon | 96 | 37 |

| Bangkok | 57 | 22 |

| Other | 10 | 4 |

| Total | 260 | 100 |

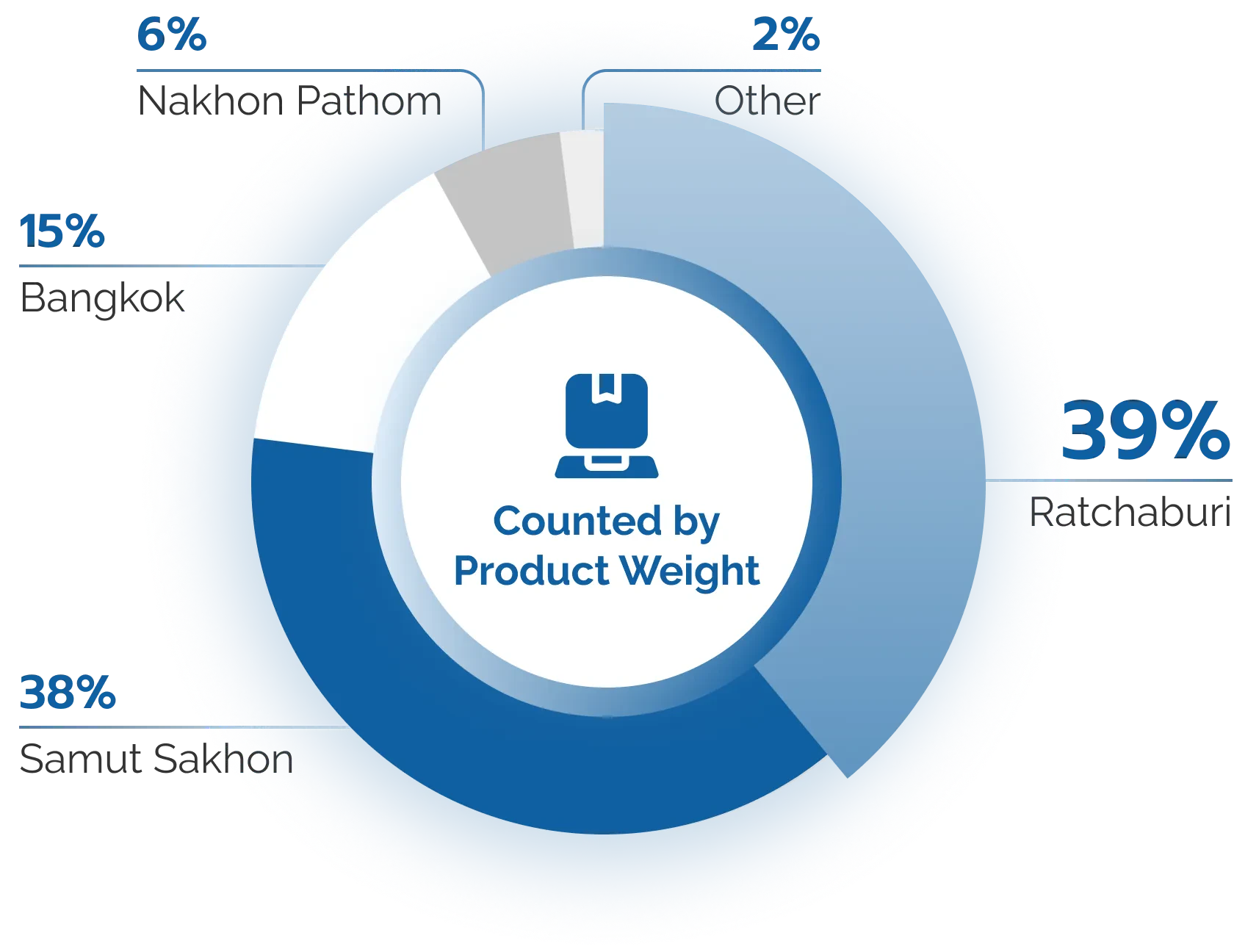

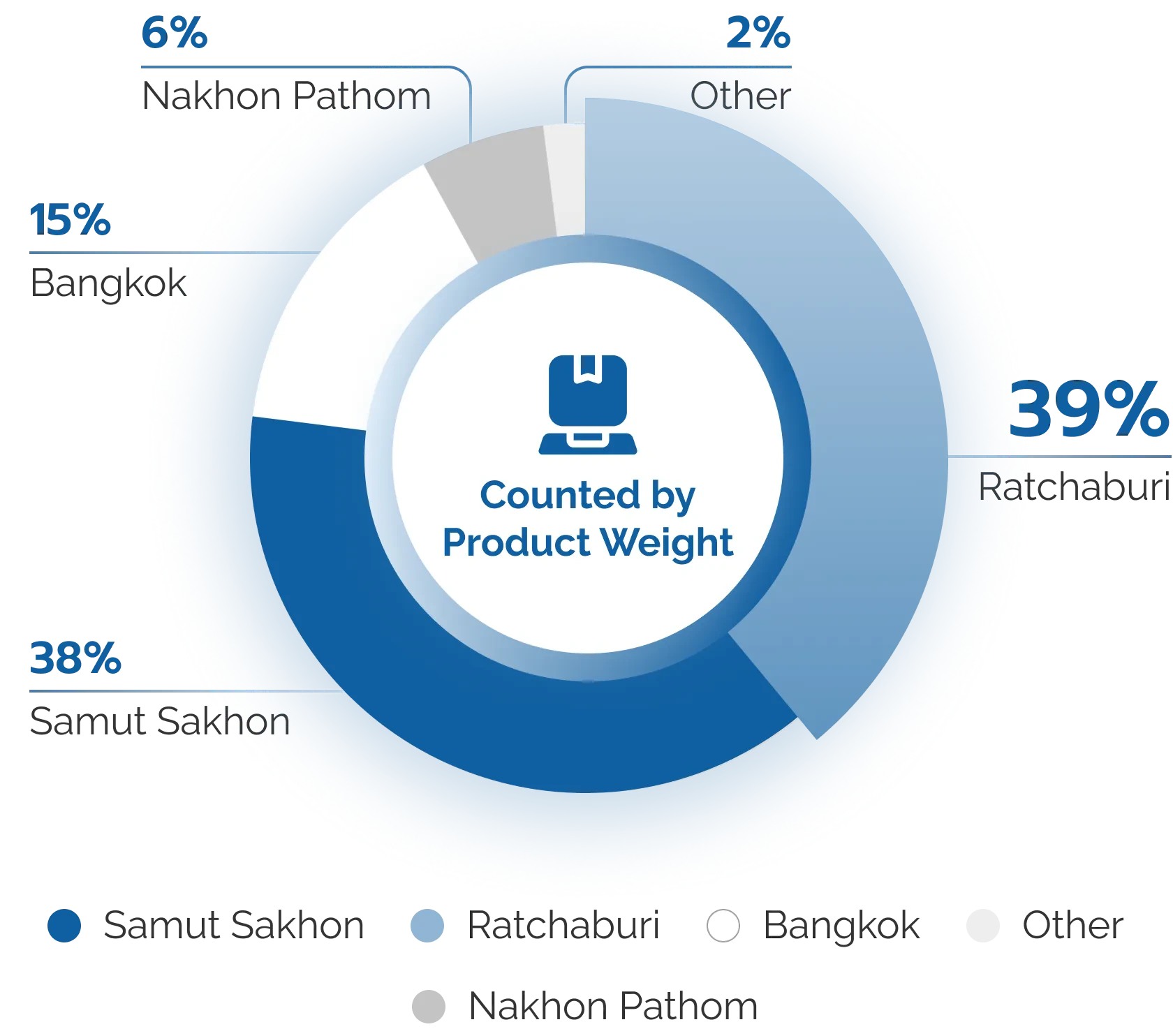

Proportion of the external service provider's location area (counted by product weight)

| The external service provider's location area | Product items | (%) |

|---|---|---|

| Ratchaburi | 140,769.98 | 39 |

| Nakhon Pathom | 22,137.26 | 6 |

| Samut Sakhon | 139,128.63 | 38 |

| Bangkok | 55,426.24 | 15 |

| Other | 6,750.72 | 2 |

| Total | 364,212.83 | 100 |

Evaluation and registration of external service providers

The objective is to establish guidelines for selecting, evaluating, grading, controlling, and developing external service providers, fostering continuous performance improvement, covering the procurement of goods/services affecting compliance with product requirements and the company’s management system. It is specified that significant external service providers are those who sell goods and services related to the company’s main products and activities. They should pass the annual evaluation against the external service provider standards. The external service provider evaluation standards consider the impact on products and business sustainability, covering aspects of quality, environment, social ethics, and legal compliance. External service providers scoring below 70% are considered to be outside the required standards, and the procurement department must develop a plan to improve the performance of these significant providers. External service providers scoring 70% and above are considered to meet the standard.

Evaluation results of external service providers for 2024

* Product-specific means external service providers with limited product listings available for the company to order.

** Standard means external service providers with no restrictions on the product listings available for the company to order.

Registration and cancellation of production source authorization

Since BLC prioritizes the quality of raw materials and packaging used in production, which directly affects product quality and production processes, as well as the quality of chemicals and equipment used in product quality control, before products are delivered to customers and consumers, it has established processes and authority for approval. This ensures that evaluations cover both quality and corporate governance aspects.

In 2024, there were 478 items registered for production source authorization, comprising 31 raw materials, 359 packaging items, and 88 chemicals and equipment used for product quality testing.